No matter whether you are a “small” workshop or a “large” automotive company: We support you in grinding/ sanding more efficiently.

Your goal is a higher quality of the grinding result? Do you want to reduce defects or wastage? Or are wear parts causing you problems? As part of our consulting service, we will support you in making your grinding/ sanding processes better.

No matter how big your company is, how many and which machines you have in use.

Our offer for consulting

in the field of grinding/ sanding technology.

From simple support with application technology problems to the optimization of entire

production plants, we support you as an independent partner who pays attention to efficiency and honesty.

- Analysis of samples

- Analysis of wear problems and rectification

- Correct choice of abrasives

- Creating and optimizing grinding/ sanding programs

- Optimization of the existing infrastructure

- Optimization according to measurement results

- Correction of quality problems

- Training for new employees

Goals of process optimization

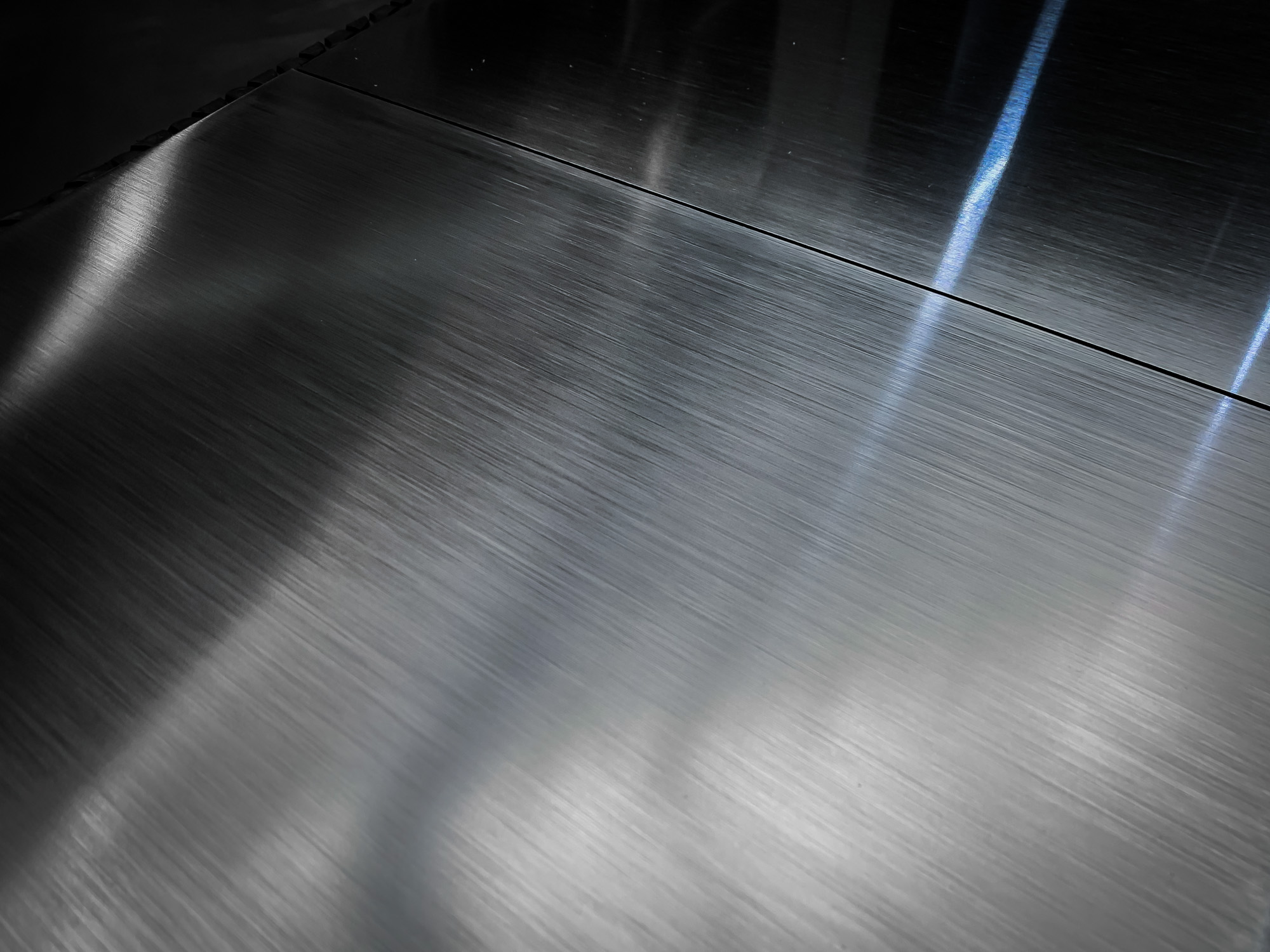

- Best possible grinding/ sanding result

Together, we look with you at the parameters you can change to reliably achieve the required surface quality and reduce rejects during production. In addition to our experience, we also consult extensive measurement results. - Reduce wear and tear

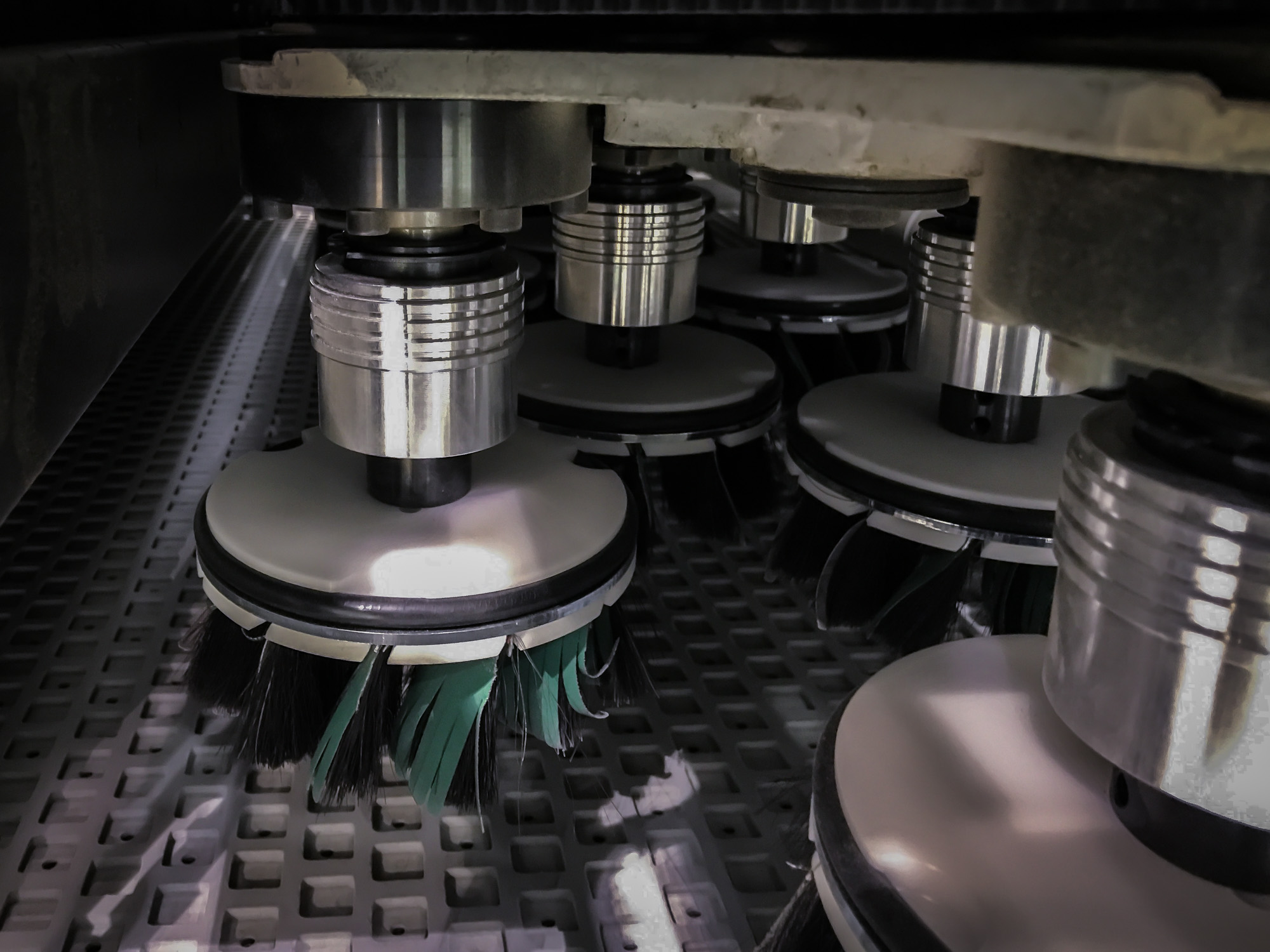

Wear parts such as cylinder heads or the grinding belt can cause high costs and failure indications. We analyze how you can reduce wear and also recommend alternative products if necessary. In addition, we look at inconsistencies on the machine (e.g. the gearbox, the aggregates), which could be the cause of high consumption. - Perfectly tuned machines

We don’t just analyze a single machine, we look at the entire production setup and determine where there is room for improvement. This allows the system to work more efficiently and saves you money. - Prevention of downtime

By identifying and eliminating potential weak points, you actively prevent downtime. In this respect, we support you in optimizing production as long as downtime has not yet occurred. - Well-established team

We train your employees in the optimal control and operation of the equipment and support new employees during onboarding. This reduces mistakes.

Our goal: Your grinding/ sanding result should have the best possible quality with a minimum of downtime.

As an independent consultant for grinding/ sanding machines and extraction systems, we uncover the problems of your production equipment and help you to fix them. This saves you time, money and nerves – because you prevent downtime and excessive wear.

Maintenance and service – independent, efficient, economical

Do you have a problem with your grinding machine or do you need external know-how how to improve your production?

Get in touch with us!

We are WDservice

Founded by two experienced application engineers specialized in grinding/ sanding machines, who want to offer the best service for your equipment, independent of the manufacturer. Learn more about who is behind WDservice and what values we represent.